PRODUCT INFO

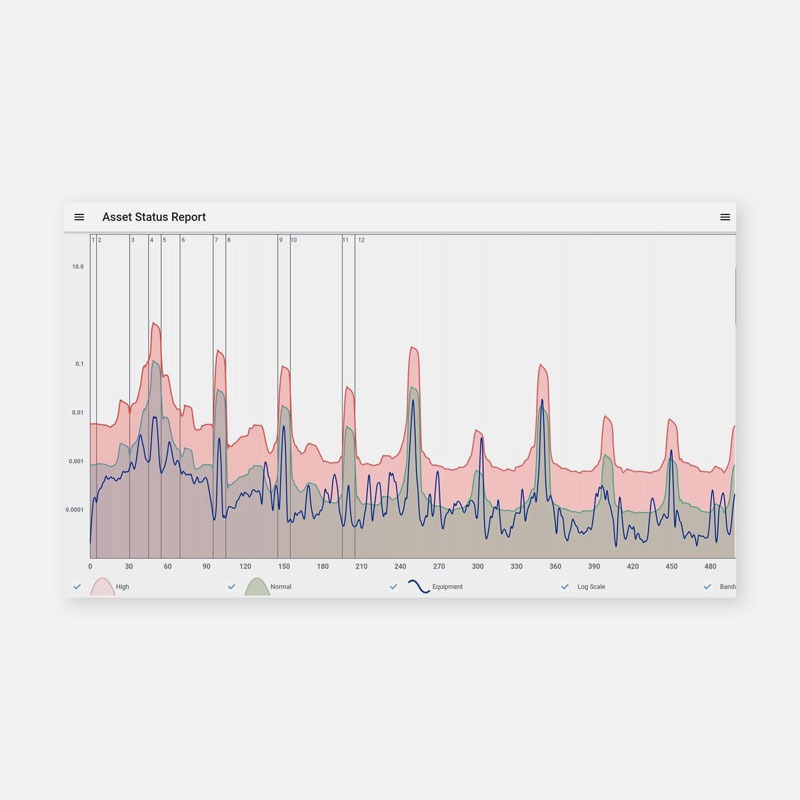

AMT Pro is designed for route-based condition monitoring of rotating equipment enabling early fault detection on the motor, drive train and driven equipment without installing any sensors on the equipment. The AMT Pro is connected to MCC Panel via three current transformers and three voltage probes, making the system straightforward to install, and use without in-depth training of personnel. The Artesis AMT Pro is installed on a special tablet with AMT Software, current transformers, and cables in one box. Artesis AMT Pro is connected to motor cables using clamp on current sensors and voltage cables. The toolkit uses three current sensors and three voltage sensors and is easy to install. It collects data from motor driven systems and saves them to the SQL database. The test duration is approximately 7 minutes allowing for 20+ tests to be performed in a day. At the end of the testing period, the toolkit generates a condition assessment report which indicates existing faults of the system, time to failure information, recommended corrective actions, and effects of these faults on energy efficiency.

Typical Fault Coverage:

- Loose foundation/components

- Unbalance/misalignment/coupling

- Transmission element Faults

- Driven equipment faults

- Bearing Faults

- Rotor faults

- Stator/insulation faults

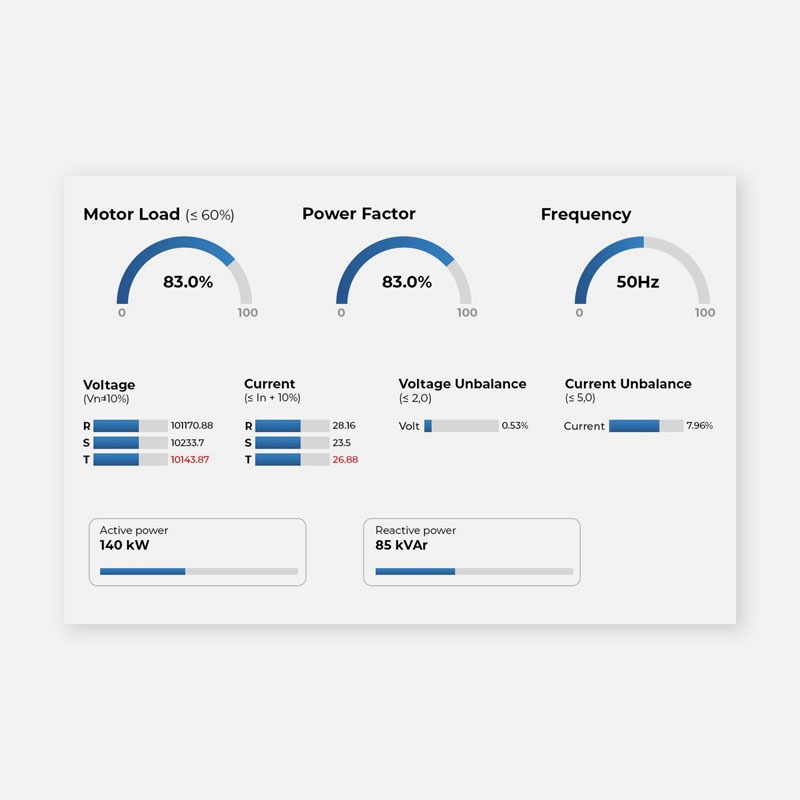

- Voltage unbalance

- Current unbalance

- Internal and external electrical faults

Process Faults detected:

- High Energy consumption

- Low Efficiency

- Cavitation in pumps

- Flow turbulence in fans, blowers

- Filter and heat exchanger fouling

- Lubrication

- Oversize/ undersize motors

- 1 x Carry Case, 5 kg

- 4 x Sets of split-core current transformers

- 1 x 400/5A, 300/5A, 200/5A, 100/5A, Class 1

- 6 x Voltage measurement cables with clips Current measurement cables