Vibration Monitoring Prevents Severe Damage on an Overland Conveyor Drive System

Engineering Dynamics Services (EDS) specialises in providing comprehensive vibration analysis and predictive maintenance services to help clients avoid costly equipment failures and unplanned downtime. This case study highlights the importance of vibration monitoring and timely intervention in preventing severe machinery issues.

Special Investigation Request

In February 2017, a client requested EDS to conduct a detailed analysis of their Overland Conveyor drive system to identify any potential issues and ensure the system’s reliability.

Data Collection and Analysis

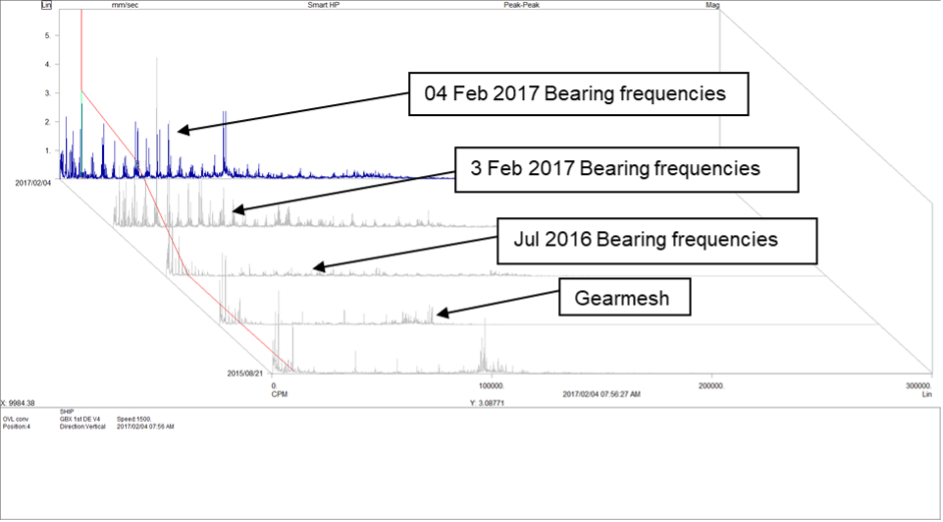

EDS captured steady-state vibration data using an ENPAC 2500 FFT analyser paired with Emonitor software. The team compared the current data with baseline readings from seven months prior, which revealed minor vibration peaks around bearing frequencies.

Findings

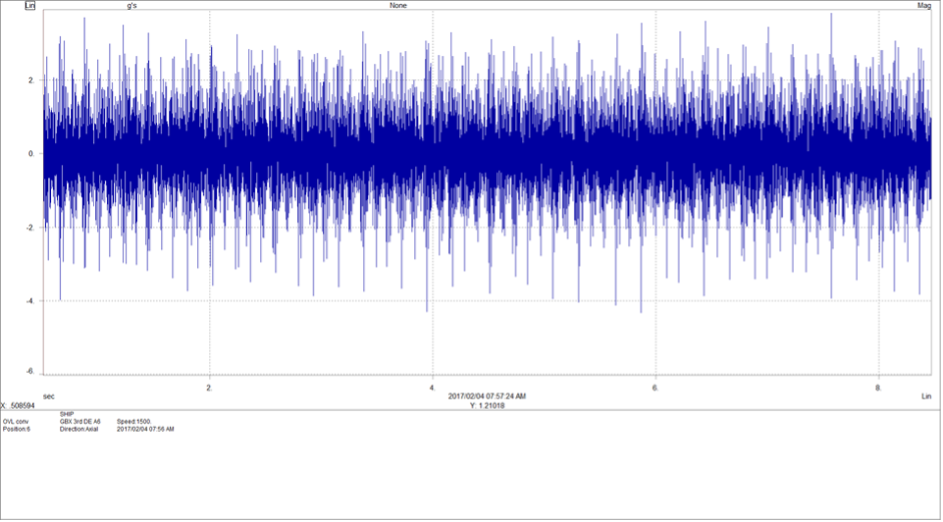

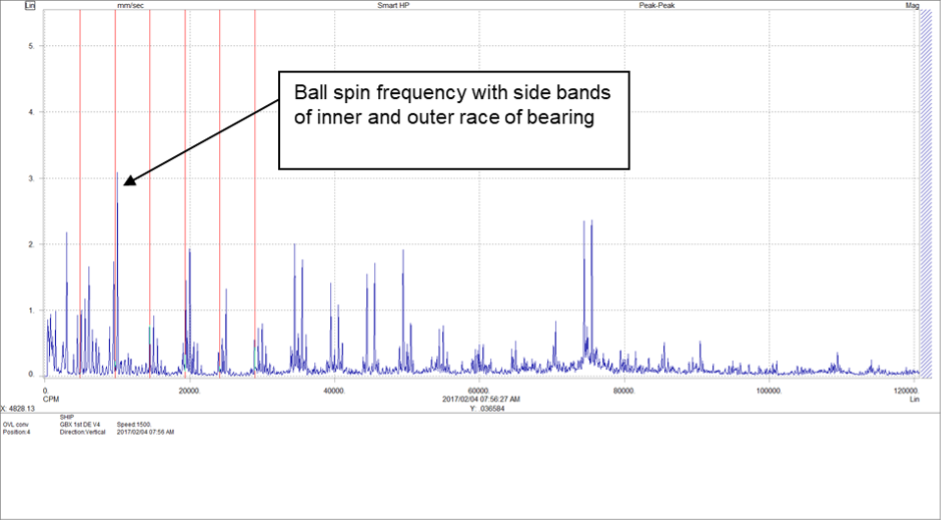

The analysis of vibration spectra and time waveforms revealed possible fault frequency peaks, indicating significant wear on the drive end (DE) bearing of the gearbox input shaft. A clear upward trend in bearing frequencies was observed, particularly since the last data capture in July 2016.

Timely Action

The client continued operating the system until the next day when the vessel was loaded. Before stopping the conveyor belt, EDS captured another set of measurements, confirming the bearing wear was still trending upwards.

Inspection and Recommendation

Upon inspecting the gearbox in place, it was found that the bearing wear had caused pit marks on the gears due to wear debris. Despite this, the gearbox was deemed fit for continued use with close monitoring. EDS recommended increasing the monitoring frequency to monthly and taking oil samples every three months to enable early detection of wear and prevent severe damage to the gearbox.

Potential Impact

EDS’s analysis indicated that if the conveyor drive had not been stopped in time, the resulting damage could have been substantial, potentially leading to significant fines from the vessel owner.

Conclusion

This case study exemplifies the critical value of EDS’s vibration monitoring services for specialised systems like the Overland Conveyor drive system. By conducting a thorough analysis, detecting the bearing wear early, and providing timely recommendations, EDS enabled the client to take proactive measures and continue operations without incurring severe damage or costly fines.

Plots