The importance of having a flat base or foundation for large rotating machines cannot be overstated. A flat base ensures that the machine is properly supported and aligned, which reduces stress and vibration, and prolongs the machine’s life. A distorted base can cause the machine housing to distort, which can lead to premature wear and tear, increased energy consumption, and reduced performance ultimately leading to machine failure.

At Engineering Dynamics we provide high-quality alignment and Easy-Laser measurement products and services for various industries. One of our recent projects involved measuring the geometric flatness of a massive new compressor crankcase base at a chemical manufacturing plant.

The compressor supplier specifically requested Engineering Dynamics to do the job, because of both our expertise and available Easy-Laser equipment to ensure precise and efficient execution. We chose to use laser-based systems to measure the surface flatness of such a huge compressor base because they are more accurate, achieve tighter tolerances and are faster than the traditional theodolite surveyor equipment.

The compressor supplier specifically requested Engineering Dynamics to do the job, because of both our expertise and available Easy-Laser equipment to ensure precise and efficient execution. We chose to use laser-based systems to measure the surface flatness of such a huge compressor base because they are more accurate, achieve tighter tolerances and are faster than the traditional theodolite surveyor equipment.

Using the Easy-Laser XT770 laser alignment system along with the D22 swivel laser, we were able to sweep 360° with a measurement distance of up to 40 metres. The system allowed us to measure the concrete base’s flatness per the international standard ISO 1101 and to within 0.01 mm/m.

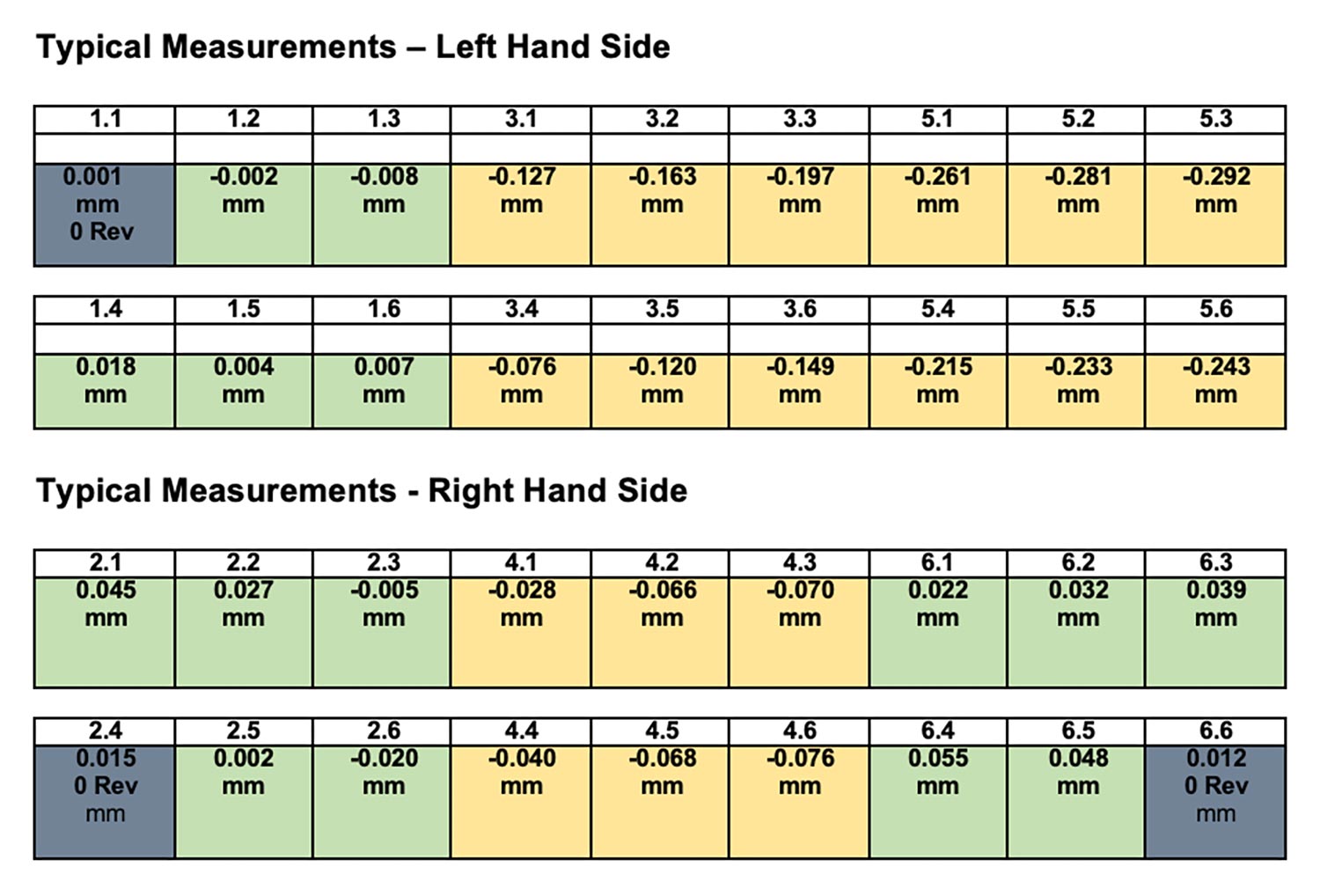

After our initial measurements revealed a total or absolute deviation value of 0.347mm on one corner, the client was able to make adjustments to the base, using our detailed reports. Our engineers returned to the client a few times to run fresh tests until they were happy that the final result (less than 0.2mm total deviation of the base) met the specifications and expectations of both the compressor supplier and the chemical plant.

Engineering Dynamics is proud of both our people’s expertise and Easy-Laser’s capabilities. Our staff have extensive training in the importance of flatness and other geometric parameters for machines, and we utilise state-of-the-art technology that allows us to perform measurements with precision and speed.

If you need any alignment equipment or measurement services for your machines, contact Engineering Dynamics today or visit our website for more information. We’re also here to help answer any questions you might have if you’re interested in getting started in this field or in upgrading your Easy-Lasers for these tasks.