Vibration Analysis Prevents Catastrophic Gearbox Failure on Cooling Fan

Partnering with Engineering Dynamics Services means integrating our expertise into your maintenance programme. With over 30 years of experience in the industry, we provide comprehensive vibration monitoring and predictive maintenance services to help clients avoid costly downtime. This case study highlights how our advanced vibration analysis techniques identified a critical issue on a cooling fan gearbox, preventing a potential catastrophic failure.

Routine Vibration Monitoring

As part of our monthly vibration checks, a dedicated Engineering Dynamics Services team detected a significant vibration issue on a cooling fan gearbox. Steady-state vibration data was captured using an ENPAC 2500 FFT analyser paired with Emonitor software.

Findings

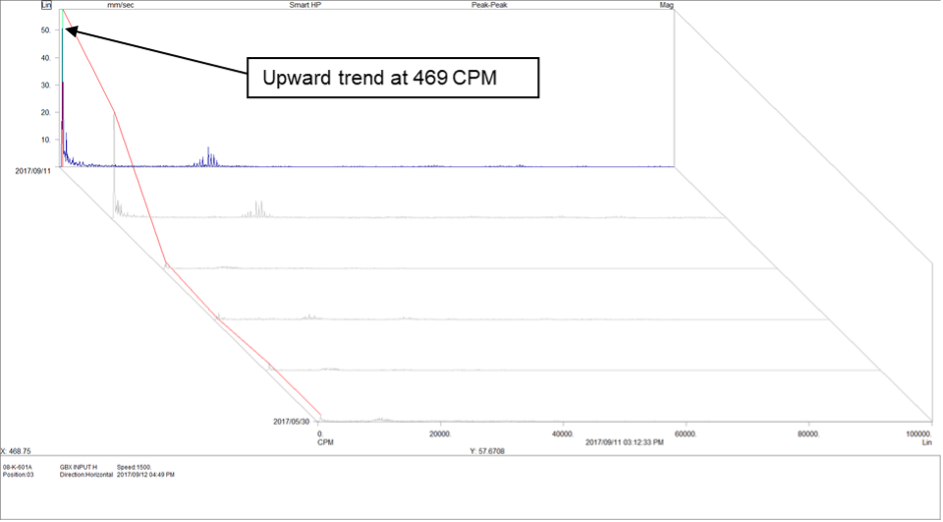

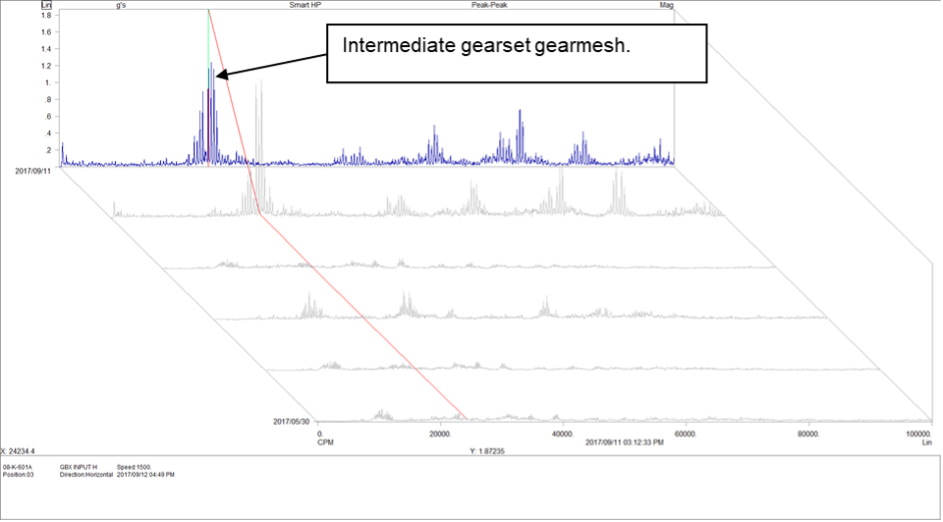

The vibration analysis revealed a sharp upward trend in the vibration spectrum at 469 cycles per minute (CPM), along with gearmesh frequency and 469 CPM sidebands. Comparing it to data from approximately seven months prior, which only showed minor vibration peaks around bearing frequencies, indicated a substantial change had occurred.

Analysis and Diagnosis

Lacking technical details on this specific gearbox, we requested a detailed drawing from the client to conduct a thorough analysis. Upon receiving the drawing, our analysis pinpointed the intermediate gear as the source of the high vibration levels. The simultaneous increase in both the 1X shaft speed and gearmesh frequencies led us to conclude that the gear was either loose on the shaft or eccentric.

Confirmation and Prevention

The next day, the client opened the gearbox and confirmed the findings – the gear was indeed loose on the shaft. The timely analysis and recommendations played a crucial role in preventing potential catastrophic failure and extensive damage that could have resulted in significant repairs and production downtime.

Benefits of Partnering with Engineering Dynamics Services

Choosing Engineering Dynamics Services over hiring a full-time in-house employee has its benefits. You save on salaries, training, and equipment costs. Additionally, our staff members become familiar with your plant and its unique needs through dedicated on-site visits. Contract clients also receive 24/7 assistance, while ad-hoc options are available for businesses with different needs.

Conclusion

This case study exemplifies the critical value Engineering Dynamics Services provides through regular vibration monitoring and advanced analysis capabilities. By identifying issues early and providing prompt recommendations, we enable our clients to take proactive maintenance measures and avoid costly operational interruptions while ensuring machinery longevity and efficiency.

Plots